Metal Core PCBs

Metal Core PCBs (Aluminum PCBs)

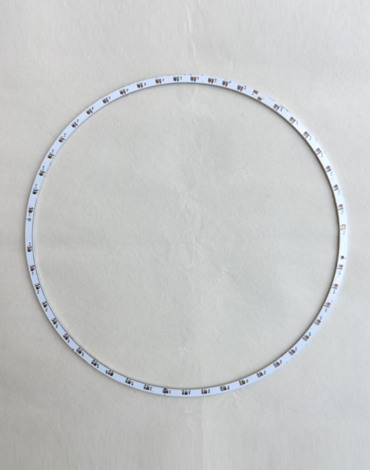

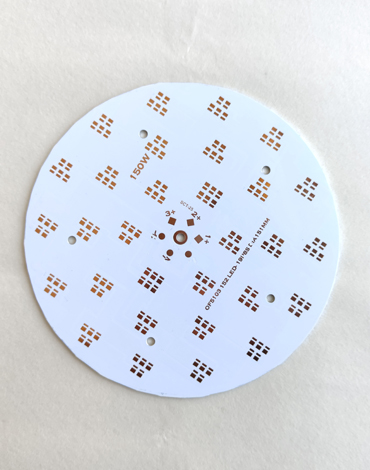

A PCB with a metal basis for the heat spreader area is referred to as a Metal Core Printed Circuit Board (MCPCB), also known as a thermal PCB or metal supported PCB. One side of the PCB is covered by a thick metal, which is generally made up of aluminium. Metal core can refer to the metal, which may be on the board's back or somewhere in the centre. The core of an MCPCB serves to divert heat away from key board components and into less important regions, like the metallic core or heatsink backing. Due to their capacity to combine a dielectric polymer layer with a high thermal conductivity for a lower thermal resistance, Metal Core PCBs can be advantageous to employ.

Compared to normal circuit boards, metal core PCBs transfer heat 8 to 9 times more quickly. Heat is dissipated via the metal core laminates, which keeps heat-generating components cooler and increases performance and life.

Frequently, conventional fans alone are insufficient to provide effective cooling for applications that generate extreme heat. As a solution, Metal core Boards with conductive cooling are the best production option. Usually, applications and products with lightnings use Metal Core PBCs, since they generate more amount of heat. These include street light safety application, general lighting applications, motor control applications, back light unit applications, and more.

Frequently, conventional fans alone are insufficient to provide effective cooling for applications that generate extreme heat. As a solution, Metal core Boards with conductive cooling are the best production option. Usually, applications and products with lightnings use Metal Core PBCs, since they generate more amount of heat. These include street light safety application, general lighting applications, motor control applications, back light unit applications, and more.